Join the Team

For over 150 years, Morgan has created a legacy as a world leader in industrial material handling systems.

Who We Are

About Morgan Engineering

We are proud to design, fabricate, and service our custom, industry-leading cranes—all in house. If creating a highly respected, custom product sounds like fulfilling work, we’d like to hear from you.

What We Stand For

Our Mission

As we enter the next industrial revolution, we are positioning our customers for success by enhancing safety, improving efficiency and delivering value through the world’s most advanced custom solutions – while building a better future for our employees and community.

Browse Our Teams

-

Sales And Support

Our technical teams are supported by a diverse group of sales and support staff. From accounting and purchasing to marketing and IT, these teams ensure that the company as a whole operates as smoothly as our products. -

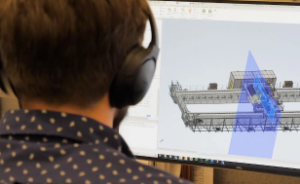

Engineering

Our full-service mechanical and electrical departments are experts at solving our customers’ most complex material handling needs. Because every crane we produce is a custom solution, our engineering team constantly collaborates across specializations to spark new innovations. -

Manufacturing

Morgan’s team of skilled workers fabricates, machines, and assembles our world-class industrial cranes. The team is strengthened by a culture of collaboration where each member is given the skills to reach their next level of expertise. -

Service

Our site services team is made up of experienced and independent crane maintenance experts. Morgan’s crane technicians travel the country to install and service cranes at customer sites.

A Local Impact

We Are Committed To Improving Our Community

We commit to improving the communities where we live and work – by investing in our employees, reducing our environmental impact and contributing to the local economy.

-

Sharing Our Expertise

Morgan’s expertise is a resource for the entire community. Programs like the safety calendar drawing competition teach local students valuable lessons about how they can be safer at home and school. -

Strengthing The Community

Morgan is dedicated to the continued growth of the Alliance and Stark County community. We believe that a strong community is beneficial to us all—and we support this goal directly and through the shared benefits of our own growth. -

Growing Together

Being a locally owned and operated business for over 150 years gives us perspective on what really matters. Our people will always be our greatest asset, and we support them and their families accordingly. -

Reducing Our Footprint

As a manufacturer, we understand that our impact is global. Morgan continually develops new technology and programs to reduce our environmental impact. This ranges from installing electric charging stations at our corporate headquarters to innovating our cranes with energy efficiency as an important goal.