Morgan Automates Coil Yard Management System for Big River Steel

/ News

Click here to watch the full video of the automated coil management system in action.

(OSCEOLA, Arkansas) May 13, 2021 – With more than 150 years of material handling expertise, Morgan Engineering continues to transform the way its customers do business. By taking an integrated approach to manufacturing automation, the company is designing, manufacturing and commissioning complex material handling systems from the ground up. This is made possible through the work of its subsidiary company, Morgan Automation Systems Inc., which leverages the latest advancements in “Industry 4.0” manufacturing technologies to help customers improve safety, reduce costs and maximize production capacity.

Morgan’s automation expertise is clearly on display at Big River Steel in Osceola, Arkansas – where the company recently designed and commissioned a fully autonomous coil yard management system. From cranes and lifters to programmable logic controllers (PLCs) and human-machine interfaces (HMIs), the system manages a variety of complex components to deliver a simple, integrated operator experience. For this project, the Morgan team had several objectives:

- To eliminate the need for outdoor coil storage, which leads to rust and oxidation;

- To optimize the use of indoor space through dense coil storage;

- To improve and track operational efficiency;

- To save fuel and manpower costs by reducing the reliance on Taylor forklifts for coil movement; and,

- To improve material tracking by removing the need for operators to locate coils.

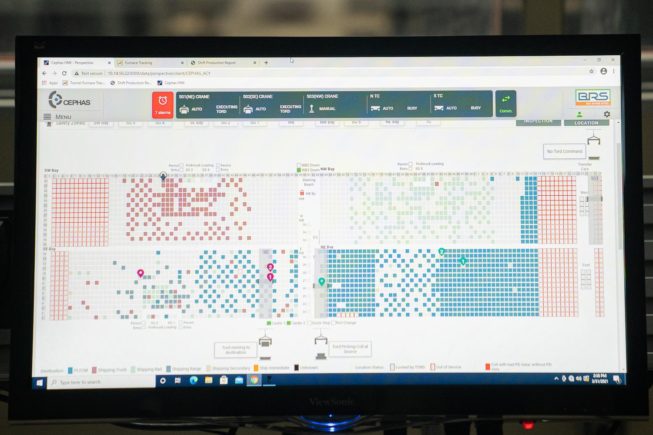

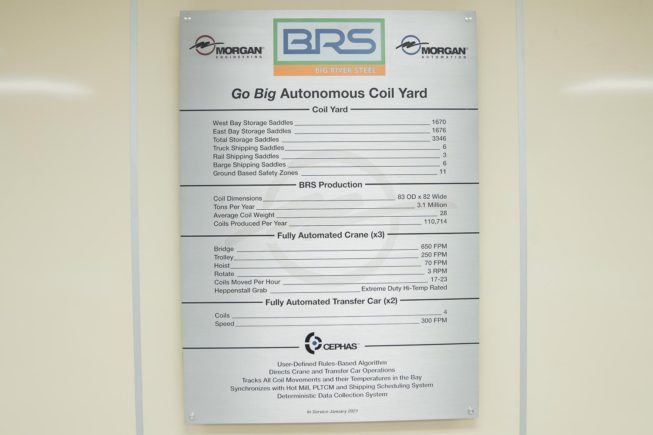

The foundation of Morgan’s coil yard management system is built upon three autonomous overhead bridge cranes and two transfer cars – all custom engineered and manufactured by Morgan Engineering. This equipment is monitored and orchestrated by CEPHAS, a proprietary automation software developed by Morgan Automation. CEPHAS uses a custom yard map to optimize the placement of every coil, logging its position for precise inventory tracking – from production to final shipment.

“When we automate operations, our team always starts with a thorough analysis of a company’s existing processes,” said Mark Sharamitaro, president of Morgan Automation. “Then, we apply our decades of engineering experience to design a custom automation system that addresses the challenges of that unique application.”

For Big River Steel’s coil yard, the process starts at the walking beam, where steel coils exit the hot mill at temperatures of up to 900 degrees Fahrenheit. Before receiving a coil, CEPHAS interfaces with the facility’s Level 3 system to gather and record all primary data associated with the coil. This includes its production specifications, as well as final shipping details.

To optimize the efficiency of coil storage, the team at Morgan programmed CEPHAS to divide the yard into four quadrants, where coils are stored according to their final destination. They include coils headed to barge shipping, truck shipping, rail shipping and Big River Steel’s continuous pickle line. CEPHAS then uses an algorithmic rules-based decision engine to optimize the placement of each coil. Thermal imaging cameras mounted on each crane ensure coils are not moved until they cool, and the order in which coils are moved is prioritized based on the facility’s workflow.

When it’s time for a coil to leave the yard, CEPHAS knows exactly where to find it and will retrieve it automatically. The system is tightly integrated with Big River Steel’s production and shipping schedule so that coils destined to leave the facility are automatically placed on a saddle where they can be handled by a forklift, or placed on the transfer car and automatically moved to the PLTCM.

Morgan Automation also integrated a number of safety-related features into the project. Each Morgan crane features a patent-pending laser positioning system that reliably reports its exact location on the yard. And a ground-based safety system is used to help protect workers from passing cranes. Sidewall sensors prevent the crane from damaging coils, while a self-centering device ensures they are always perfectly positioned.

Morgan’s inventory management system uses low production-demand times as an opportunity to “defrag” or reorganize the yard – filling empty storage spaces and grouping common destination coils together. This process eliminates wasted space and ensures the coils are always stored to enable the most efficient utilization of all equipment.

Meanwhile, CEPHAS uses the thousands of data points generated by the system to provide unparalleled insight into the efficiency of its operations. All this data is displayed in a simple dashboard that provides instant visibility to real-time KPIs.

“When the system is in operation, every movement is carefully orchestrated, and every sensor is continuously monitored and logged with its time stamp,” said Sharamitaro. “This real-time data collection and evaluation allows the team at Big River Steel to continually identify and improve operational performance.”

The results speak for themselves. Since commissioning the Morgan system, the facility has:

- Improved operational efficiency;

- Increased machine availability and reliability;

- Reduced fuel costs;

- More efficiently utilized personnel labor; and

- Reduced cycle times.

As Morgan Automation grows, the company remains committed to design, engineer, build and install every system from start to finish – making Morgan a one-stop-shop for any automation solution.

“If your process has challenges that can benefit from automation, we have the expertise to develop a custom solution for you,” said Sharamitaro.