Crane Inspections: Recommendations, Requirements, and Schedules

/ Blog

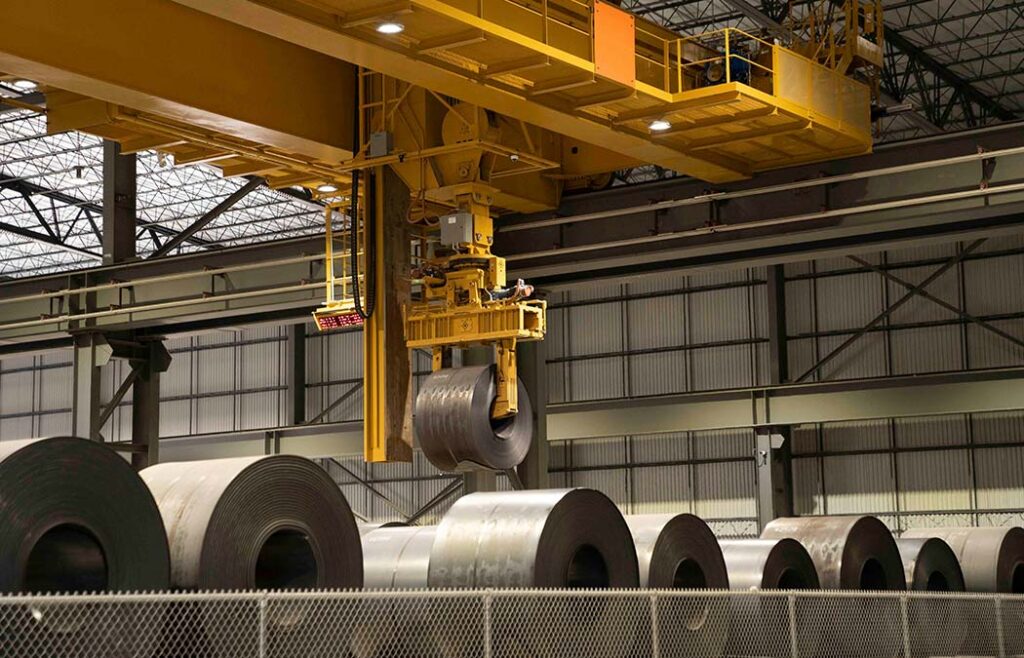

Regular crane inspections are crucial to maintaining your overhead bridge crane’s performance and ensuring crane safety. Understanding when your equipment needs an inspection can be complex, but guidelines provided by OSHA 1910.179 offer clear directives.

To understand the frequency of overhead crane inspections, consider:

- The crane’s usage

- The crane’s class

- The crane’s components

Understanding Crane Classes and Inspection Timelines

The class of your crane determines its approximate inspection timeframe:

Frequent Inspection Chart

| CMAA Service Class | ASME B30.2 Service Class | # of shifts/day and frequency of inspection | |||

| Stand-By | 1 Shift | 2 Shifts | 3 Shifts | ||

| A | Normal | Semi-Annually | Semi-Annually | Semi-Annually | Semi-Annually |

| B | Normal | Monthly | Monthly | Monthly | |

| C | Normal | Monthly | Monthly | Semi-Monthly to Monthly | |

| D | Heavy | Monthly | Semi-Monthly to Monthly | Weekly to Semi-Monthly | |

| E | Severe | Weekly | 3-5 Days | Daily | |

| F | Severe | Daily | Daily | Daily |

Periodic Inspection Chart

| CMAA Service Class | ASME B30.2 Service Class | # of shifts/day and frequency of inspection | ||

| 1 Shift | 2 Shifts | 3 Shifts | ||

| A | Normal | Annually | Annually | Annually |

| B | Normal | Annually | Annually | Annually |

| C | Normal | Annually | Annually | Annually |

| D | Heavy | Annually | Semi-Annual to Annual | Semi-Annual |

| E | Severe | Quarterly | Quarterly | Quarterly |

| F | Severe | Quarterly | Quarterly | Quarterly |

Frequency of Crane Inspections: Adhering to OSHA 1910.179 Standards

According to OSHA 1910.179, frequent inspections should occur daily to monthly, while periodic inspections range from monthly to yearly. For us at the Detroit, Michigan branch, we also follow MIOSHA. As a rule of thumb, a class C crane requires a frequent inspection every 100 hours of use, and a periodic inspection every 500 hours. This guideline helps in tracking and scheduling inspections effectively.

New or modified overhead cranes should undergo a thorough crane inspection and load testing before their initial use, ensuring they start on the right foot.

When scheduling a crane inspection service with Morgan Site Services, we’ll inquire about:

- The number and types of cranes

- Crane capacities and heights

- Manufacturer details

- Usage rates

- Presence of manlifts

- Site safety protocols

These details help us prepare for an on-site crane inspection that meets your specific needs and ensures compliance with overhead crane safety standards.

It is always encouraged that everyone who comes into contact with overhead cranes does their own research into OSHA requirements as well.

Common Issues Identified in Crane Inspections

Only OSHA-certified inspectors can conduct the necessary crane inspections outlined by OSHA. Critical issues identified include problems with wire ropes, brakes, and electrical components. Early detection of these issues can significantly reduce crane downtime and enhance safety standards.

What An Excellent Inspection Looks Like

Our expert team not only conducts initial overhead crane inspections but also provides detailed inspection reports post-service. We value transparency, so any issues, deficiencies, or crane repair needs are communicated clearly and promptly. Typically, our team can be on-site for follow-up actions of scheduling a crane inspection.

Why Choose Morgan for Your Crane Inspection Needs

At Morgan, we build lasting relationships with our clients, gaining deeper insights into your overhead cranes and operational needs with each service. We pride ourselves on handling all aspects of crane service in-house, from repairs, part replacement, and upgrades to future inspections.

Improve the safety and efficiency of your operations with Morgan’s comprehensive crane inspection services. Schedule your crane inspection today.