Piece by Piece: Overhead Cranes Explained—Part 1

/ Blog

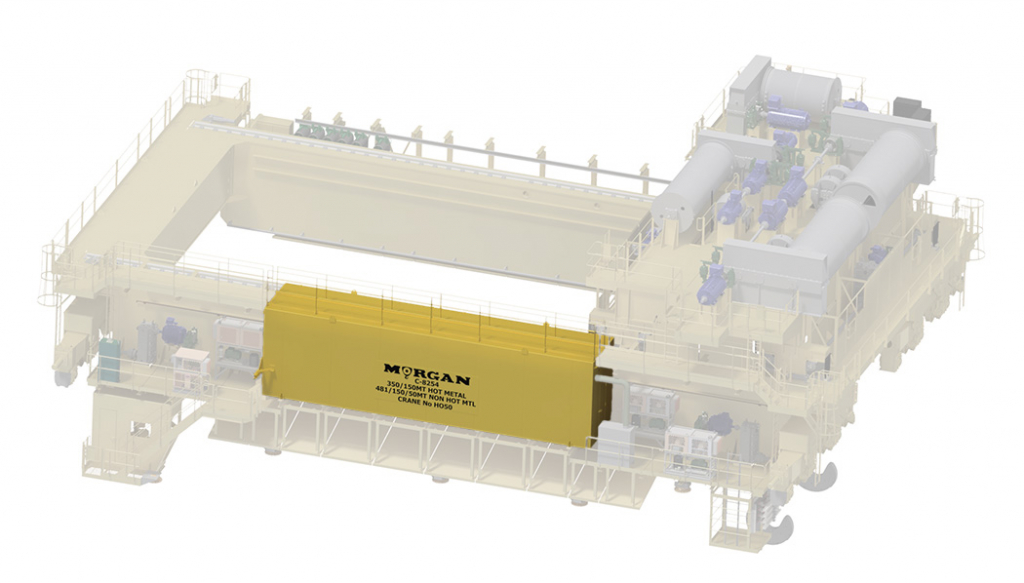

Anyone who works with cranes works with technology from ancient times. Historians believe the first basic crane was invented by the Greeks in 700-650 B.C.1 Morgan introduced the first steam-powered overhead traveling crane for use in steel mills in 1874. This invention revolutionized the means in which steel was produced; a process that previously required 10–12 men pulling a ladle pot on a cart for capturing the molten steel from the furnace and then pulling the cart to a place in which it could be poured into ingots. And in 1881, Morgan introduced the electric-powered version of the overhead traveling crane to improve the safety and efficiency of the machines we have used for centuries.

Overhead cranes are an integral piece of equipment for many streamlined processes; it is critical to have a strong foundational knowledge of how an overhead crane works, the variations of overhead cranes that exist, and the ability to identify the key parts that enable the crane to perform its essential functions.

What is an Overhead Crane?

An overhead crane is a permanent fixture within a facility. More times than not, an overhead crane is strategically planned for in the architect’s drawings as they will determine the required placement for runways, doors, light fixtures, network connectivity, power sources, etc.

An overhead crane may even be installed prior to the construction’s completion as to allow for easier placement, assembling of the crane, and installation of large production equipment on the floor below. This is one of the basic differentiators of overhead cranes from mobile cranes. As mobile cranes may be moved at will, easily replaced when needed, and are often used temporarily for things like construction or maintenance.

Some of the key benefits of an overhead crane include their custom nature, allowing them to be an active member of your operations whether you are loading scrap metal, handling ingots, or moving parts for assembly. Overhead cranes are elevated on the crane rails, leaving the general work area below clear.

Types of Overhead Cranes

Four main variations of overhead cranes exist:

- Bridge

- Gantry

- Semi-Gantry

- Jib

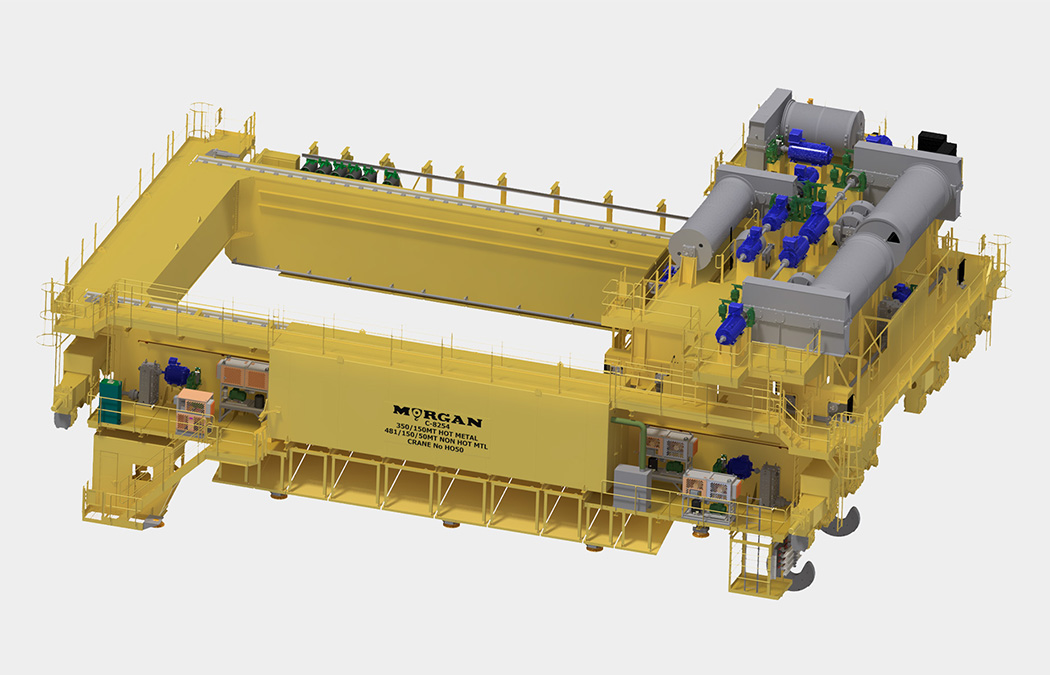

Bridge Crane

A bridge crane rides on an elevated runway, so it is most ideal for processes that involve moving material from point A to B, typically within a closed structure. A common application for an overhead bridge crane would include a ladle crane which transports and unloads a ladle filled with liquid steel to a position for casting in the production of steel.

Gantry Crane

A gantry crane runs on a ground-level track, with the bridge elevated on legs. This structure gives most of the advantages of an overhead crane without requiring an overhead crane runway. Gantry cranes lift loads, typically in outdoor environments. Gantry cranes are utilized for storage yards as well as loading and unloading trucks, rail cars, and barges.

Though gantry cranes are rarely seen indoors, it is possible to find them along production lines or other similar uses to outdoor gantry cranes. There are several types of gantry cranes, each serves a specific purpose. For example, a rubber-tired gantry crane makes for more flexibility in its location, as the rubber tires allow it to be easily moved.

Semi-Gantry Crane

A semi-gantry crane is generally used where the end of the crane is adjacent to a building so that the crane runway can be supported by building columns. It combines the features of the gantry and the overhead traveling cranes. It features two runways, one above the other.

It is common to find this indoors for industrial plants to move finished products and raw materials through the production process, power plants, and more. Semi-gantry cranes can be paired with a bridge crane that runs on rails above it. In this scenario, semi-gantry cranes isolate work areas into cell-based work zones.

On the rare occasion that a semi-gantry is used for an outdoor application, it is typically larger than one found inside. An example of this would be an ore bridge that have applications such as bulk material handling of iron ore; the starting process in steel production.

Jib Crane

Unlike an overhead crane, the jib crane consists of a boom mounted on a pivot pole or fixed to building columns – both are popular options. It is used to lift loads where work is confined to a cell-based work zone. Jib cranes are usually paired with other cranes to complete a small portion of a larger project. Unlike the other cranes, jibs don’t move between two different points, rather they cover a set circumference area.

Key Components of an Overhead Crane

Overhead cranes have three main motions:

- They need to lift vertically

- Move within the set range along rails

- Move horizontally

Each component of the crane supports at least one of these motions.

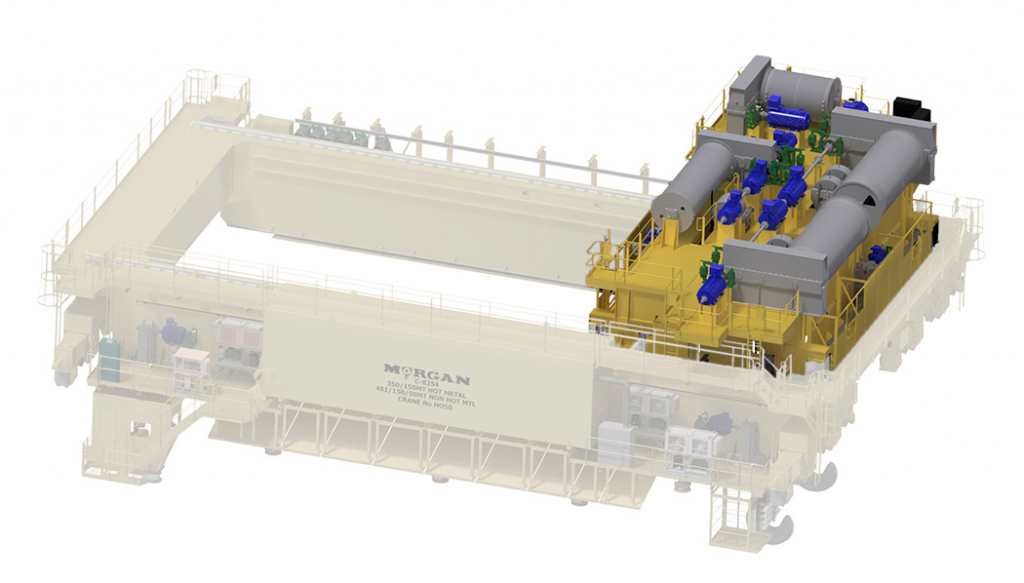

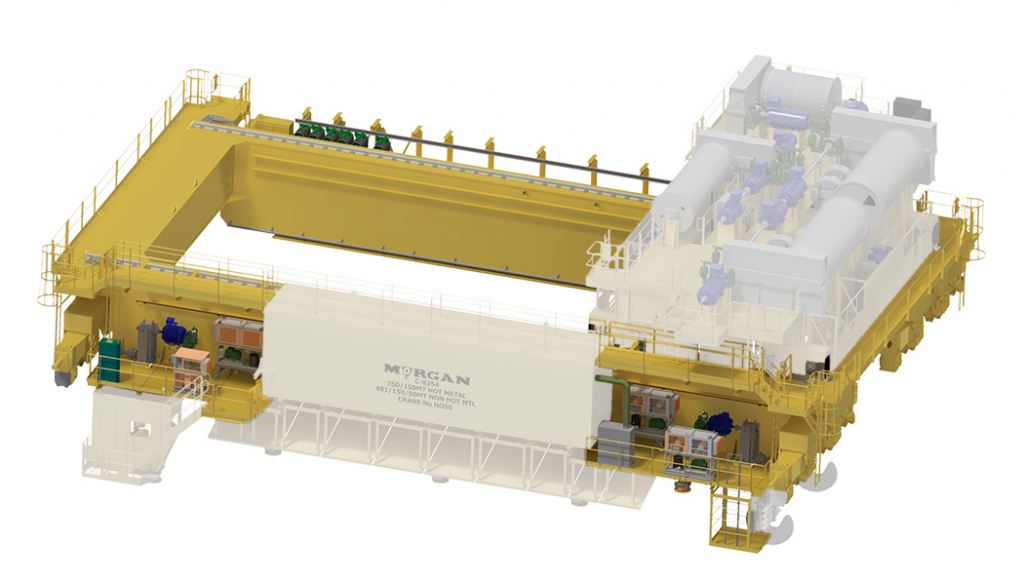

Trolley

The trolley is a wheeled mechanism that holds the hoist responsible for the vertical motion. The trolley moves across the length of the bridge, giving the crane its first horizontal motion. The trolley can be fitted with multiple hoists that can handle different capacities.

Bridge

A bridge is the main supporting structure of a crane consisting of a walkway, railing, shafting, drive, girders, and trucks which travel along runway rails. It supports the trolley and a load by moving it the length of the building structure to provide the second horizontal motion.

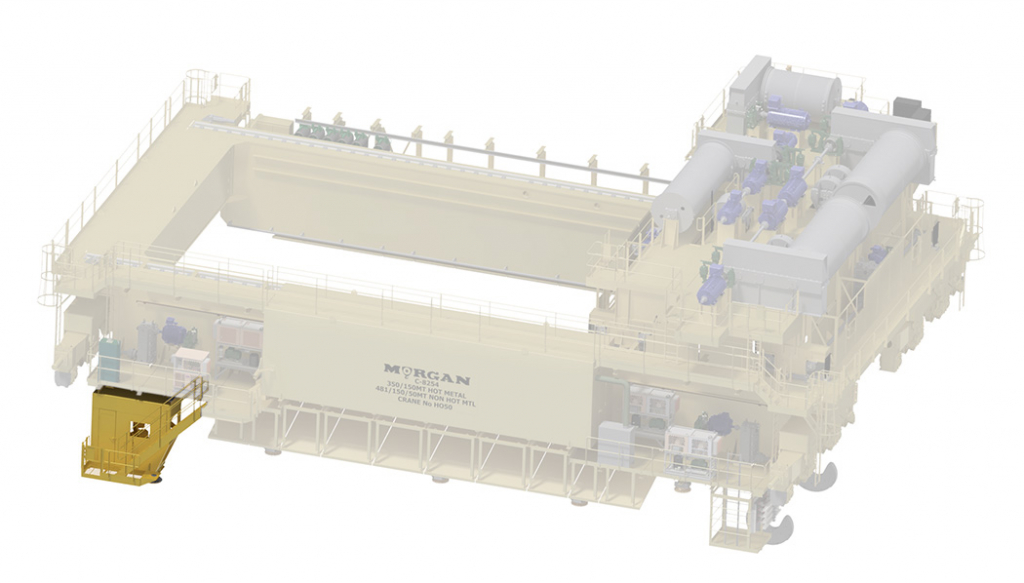

Cab

Many overhead cranes also have a cab, which is the operator’s compartment on a crane. Cabs are utilized in high-production processes requiring a full-time operator or where the operator needs an elevated vantage point. Cabs are always elevated and located by the bridge or trolley. The elevated vantage point allows the operator to see everything below them to make the safest operating choices possible. If the crane is used on a more part-time basis, operators may use a radio box to easily move items where needed.

Control Houses

A control house, or control panel, is where all the electronic parts are contained. The house allows for the electronics to be climate controlled and is responsible for making the three motions possible. Integrating electric components into cranes has been essential for improving safety. The electronics provide the means of operating the high-voltage power drive with low-voltage operating controls by means of cab masters, radio controls, or pendant controls. Incorporating computers and PLC’s into the electronic package allows for additional safety, maintenance information, and production statistics most common in AC voltage drive control applications. These include Crane Management, automation, CEPHAS storage tracking, etc.

All these overhead crane components can be customized to allow for different size loads and unique movements, like rotations.

Learn More

Coming soon: Follow along with the Piece by Piece: Overhead Cranes series as we work through the parts of an overhead crane. New updates will be announced on our social media regularly.

Are you interested in learning more about what customizations could be designed to build your company a perfectly engineered crane? Contact our team today.

1 Grossman, David. “The Crane Has Been Perfect since 700 B.C.” Popular Mechanics, 27 Aug. 2019, www.popularmechanics.com/science/archaeology/a28833389/crane-history-construction-ancient-greece/