Sustainability in Manufacturing: The Role of Crane Modernizations & Upgrades

/ Blog

The steel industry has a reputation for being a heavy polluter, but anyone in the industry today knows we have all worked tirelessly to minimize our environmental impact. In fact, the industry is working to be entirely carbon neutral by 2050. At Morgan Engineering, we have initiatives to recycle, reuse, reduce, and even upcycle nearly every waste product we produce, exemplifying our dedication to sustainable manufacturing processes.

Morgan Engineering’s Carbon Footprint

The scope of the steel industry is worldwide. Every step of the process must be accounted for to have an idea of the environmental impact it has.

Including the industry as a whole, anyone’s carbon footprint is broken down into three sections:

- Scope 1: any emissions that a company directly participates in (gas for company cars, cutting oils, diesel fuel, etc.)

- Scope 2: power consumption, natural gas, water usage, air

- Scope 3: employees and vendors consumption of scope 1 and 2

These statistics can be plugged into a formula that gives a total estimation of a carbon footprint. This number gives a reference point for the impact a company is having on our environment. It can also bring to attention aspects that can be improved.

There are multiple ways to earn points back. For example, our sustainable manufacturing practices are highlighted by the filtration pond in front of our office headquarters in Alliance which features plants that naturally clean the water to drinking standards before it leaves our campus.

E-waste program

One of the most difficult products to recycle is electronics. Housed in plastic, the precious metals, and possible biohazards each need to go through different processes to be disposed of properly. It is important that everyone is a good steward and responsibly disposes of electronic waste.

At Morgan Engineering, we have always recycled our past technology but now we are working to formalize the system. Our CIO has worked to consolidate the recycling from our several buildings into one that can be better monitored.

Our IT department has consolidated over 3,000 pounds of e-waste and is researching local e-waste companies that align with our values and requirements. Our CIO is looking to eventually have an option for employees to bring in their personal technology to be recycled as well.

Although recycling is always a priority, we don’t aim to recycle technology that could still be useful elsewhere. This is where upcycling plays a role. We will also be donating devices that can be beneficial for people who may not have easy access to the technology they need.

It may seem tedious to recycle or upcycle technology, but we see it as our responsibility as people who acknowledge their inherent impact on the environment. Safety and community aren’t values we say, they’re values we act on. Just as we clean up oil spills in our plant, we should be taking care of devices in a responsible manner.

It’s not only companies that can assume responsibility for recycling their devices properly.

These devices and more can be donated to your local facilities:

- Cables

- Laptops

- Cameras

- DVD Players

- Fans

- Hair Dryers

- MP3 Players

- Video Game Systems

- Lithium Batteries

Always check with your local waste management facility for a complete guide of what they will and won’t accept.

Energy Saving Crane Modernizations & Upgrades

A focal point of our efforts is to contribute to the steel industry’s carbon-neutral goal is our commitment to crane modernization, specifically through DC to AC conversions. This crane technology not only enhances the operational efficiency of our cranes but also significantly reduces power consumption—by as much as 72%.

When a crane lowers a load, the energy used was once burned off as heat, but it can now be redirected back to the power grid. The energy savings can then be used by other equipment.

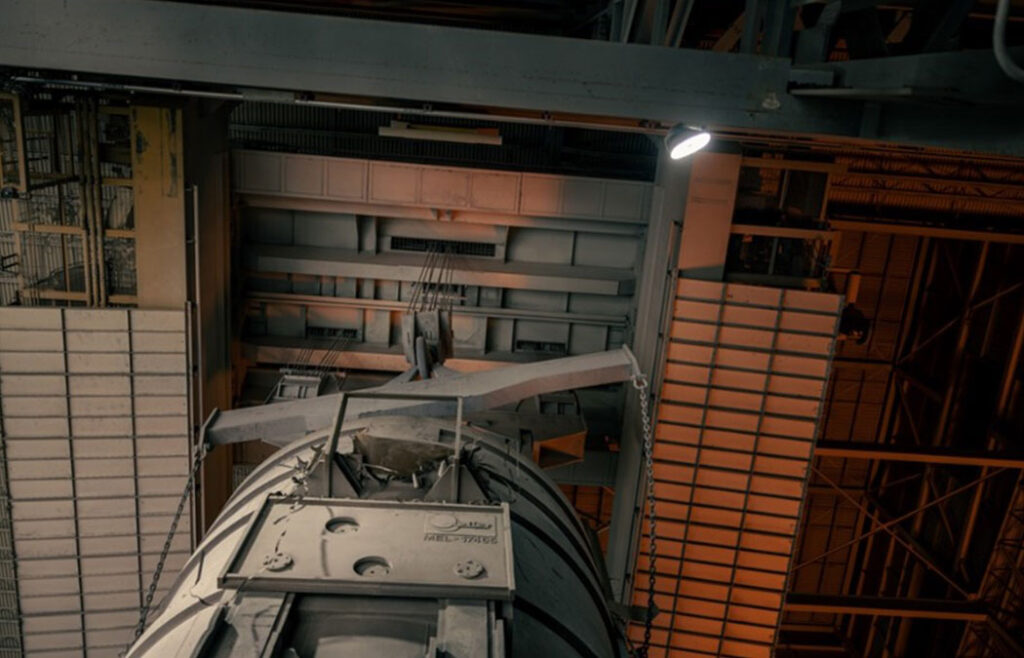

We recently upgraded our largest crane in Morgan Engineering’s shop with AC technology, which gave us the benefit of regenerative electricity and allowed us to update the controls, making it easier for our crane operators to use it. This is a significant milestone in our journey toward sustainability in manufacturing.

Transform Your Operations: Embrace Sustainability with Morgan Engineering

If your company wants to improve its sustainable manufacturing practices, a DC to AC upgrade for your crane can help achieve that goal. By making this simple switch, you can contribute to a greener future while also improving your business’s efficiency. Contact us today to get a crane modernization quote.