Morgan: Your One-Stop Shop for Overhead Crane Solutions

/ Blog

The origins of the term “One-stop shop” date back to the development of the supermarkets in America that have become the norm of today. Prior to this 1910’s invention, Americans needed to travel to several specialty stores to check off items on their grocery lists, a task that would consume much of the day[i]. From its inception to today, the supermarket has evolved to provide convenience, time-savings, and cost reductions in carrying products from food to toiletries to clothing and more. Truly a one-stop shop for all your needs.

As a leading overhead crane manufacturer, Morgan prides itself on being the “one-stop shop” for overhead cranes, encompassing a comprehensive range of crane services. At our one shop, our customers receive services ranging from the initial crane designs to a lifetime of service of their overhead cranes. Through providing engineering, automation, manufacturing, commissioning, and service, our customers can capitalize on the same benefits of the original one-stop shop: convenience, time-savings, and cost reductions.

Adding Convenience to the Overhead Crane Industry

In 2005, when I stepped into the role of CEO, I saw a need for us to go back to our roots. Morgan began as a full-service provider in the overhead crane industry, but between the 1960s to 1990s the company strayed from that ideal.

A team that can complete everything a customer could need in-house fills a gap in the market.

Our team will see your crane’s design from beginning to end, ensuring that every aspect of your crane’s lifecycle is meticulously managed by our team of experts, from crane installation to crane replacement parts and site services.

Our new talent learns from those who know the industry inside and out to be sure we’re never without the knowledge we need to provide the world-class service Morgan has built its reputation on. By taking a holistic approach, we not only foster strong relationships with our clients but also ensure that your overhead crane is always in capable hands.

For our customers, this means we build a relationship over the crane’s lifetime. With Morgan, once you have your crane design, you also have a team to install, maintain, and upgrade your crane down the road as new technological advancements become available.

Our Efficient Crane Manufacturing Process

Over the last few decades, we have worked to steadily improve the communication between each area of our engineering, manufacturing, and service departments as well as with our customers.

Morgan works in a circular pattern. Each department works with all others to achieve the seven steps of the process wheel. This provides synergy among us, from crane design to crane automation, every step is seamlessly integrated. Our process is laid out to be transparent. All we need are the customer’s ideas to begin executing another state-of-the-art crane.

As we start on a new crane, the customer can track the progress of our work through our Customer Portal. Effortless collaboration is possible with straightforward lines of communication.

In our industry, miscommunication between the customer’s expectations and the company they’re working with isn’t uncommon. For Morgan, direction between departments is seamless allowing us to double and triple check that each decision has the customer’s needs always at the forefront.

Rather than having to keep track of several contractors, our customers only need to communicate with our team. We are happy to assume the extra responsibility of the entire process being under our name because it’s how we ensure a project is done right, start to finish.

Handling the entire process, from crane design to crane manufacturing to crane automation, provides our customers with several benefits:

- Seamless Integration: Our engineers can optimize the crane design specifically for automation. This ensures smooth integration between mechanical components, electrical systems, and automation features.

- Efficiency: By considering crane automation requirements from the outset, we eliminate potential retrofitting challenges. The crane is purpose-built for automation, minimizing wasted effort and time.

- Holistic Cost Consideration: We account for all costs upfront, including design modifications, automation components, and crane installation. This transparency helps customers make informed decisions.

Understanding Total Cost of Ownership for Overhead Cranes

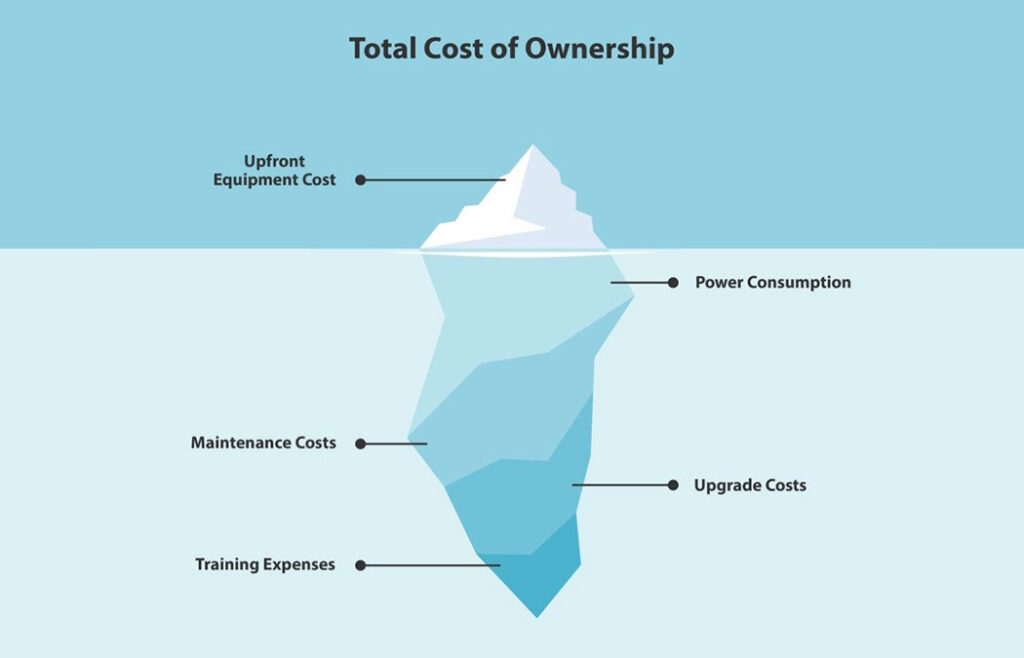

When assessing capital equipment, it’s crucial to account for the total cost of ownership, which includes all the associated additional costs. I often use the iceberg analogy to illustrate this point. Imagine an iceberg—the visible portion above the waterline represents the initial investment cost. However, beneath the water lies a mass three times larger, symbolizing the hidden costs of operating the investment.

At Morgan, we go beyond the initial purchase price to evaluate the total cost involved in owning a crane. Our expertise in designing and manufacturing cranes that are optimized for automation from the outset not only ensures smooth operation but also considers long-term savings on maintenance, power consumption, and training. Sometimes, a higher upfront cost can lead to greater cost-effectiveness over the investment’s entire lifetime.

Morgan’s innovations have led to thousands of patents and the manufacturing of more than 23,000 cranes that last decades, even centuries when treated with frequent inspections. With a Morgan crane, not only will you be investing in the highest quality overhead crane, but you’ll also only have one warranty. The stress of aligning multiple warranties for each aspect of the crane; from crane design to automation, and the crane installation, isn’t a concern when everything is done by the same team.

The Role of Warranties in Cost Management

Crane manufacturer warranties are crucial for safeguarding your investment. These warranties typically cover defects in materials and workmanship.

However, manufacturers often void warranties if the product is not installed or handled according to their instructions. This means that improper crane installation or deviations from specifications can jeopardize warranty coverage.

There are several key factors contractors are responsible for in their design warranties:

- Design Professionals: Architects and engineers issuing design specifications play a pivotal role. When they specify particular materials or equipment, they communicate that these choices are suitable for the project.

- Hidden Costs: If the design conflicts with installation instructions, contractors adhering strictly to the design may inadvertently void the warranty. The manufacturer won’t honor it due to non-compliance with instructions.

- Liability: Design professionals may be held liable if their design leads to warranty voiding. Proper alignment with warranty requirements is essential.

Contractors execute the project using their means and methods. If these deviate from the manufacturer’s guidelines, it can void the warranty. Contractors often provide their own parts and labor warranty, which may meet vague or ill-defined warranty specifications. However, this doesn’t replace the manufacturer’s warranty.

Morgan’s holistic one-stop-shop approach to crane design, crane manufacturing, and crane automation ensures that all components are perfectly integrated for optimized performance, enhancing long-term value. Oppositely, automating a crane designed by others may save upfront costs, but it can lead to design constraints, compatibility challenges, and hidden expenses.

This dilemma forces customers to face a trade-off by choosing between minimizing costs by working with multiple contractors versus ensuring warranty compliance. While cost savings matter, prioritizing long-term value—reduced downtime, efficient operation, and warranty protection—is essential.

Customers must weigh the benefits of cost savings against the risk of voided warranties. Collaborating closely with reputable contractors and aligning crane designs with warranty requirements can strike the right balance and ultimately in the end cost more.

Discover the Morgan Difference

Balance between cost and quality has always been a debate. The real question lies in your company’s values. Reflect before any major decision about where cost-effectiveness, efficiency, and convince fall in your list of priorities. This will tell you if working with a one stop shop like Morgan is a good fit.

Visit us to see our process in action, from crane design and automation to comprehensive site services. Let Morgan be your partner in navigating the complexities of crane ownership.

[i] “How Supermarkets Took Over.” Documentary. Get.factual, 2023.

https://www.youtube.com/watch?v=NagWOEpB1Os.