Crane Differences Beneath the Surface

/ Blog

It goes without saying that many cranes’ namesakes aren’t hard to decipher. Ladle, scrap, and coil cranes can be easily understood, but what helps these machines do their jobs beyond the obvious below the hook devices they’re fitted with?

Understanding Crane Class

A deep understanding of the environment a crane will be in is vital to an innovative and efficient design. The CMAA crane class system, which ranges from A to F, guides professionals in determining maintenance needs over time. At Morgan, we specialize in custom cranes tailored for the demanding E and F classes.

Heppenstall grabs during production

Class E cranes are commonly found in harsh environments like scrap yards, cement mills, lumber mills, and container handling. These severe service cranes, equipped with advanced below the hook lifting devices like magnets and Heppenstall grabs, are designed for heavy-duty tasks for twenty or more near capacities lifts per hour.

Class F cranes demand the utmost reliability and often feature solutions for extreme jobs. As continuous severe service cranes, their design focuses on enduring near-capacity loads throughout their lifetime.

The frequency of necessary inspections for each crane class increases with the severity of load weight and conditions. Thorough and regular crane inspections demonstrate respect for the job cranes do and help keep them in working order.

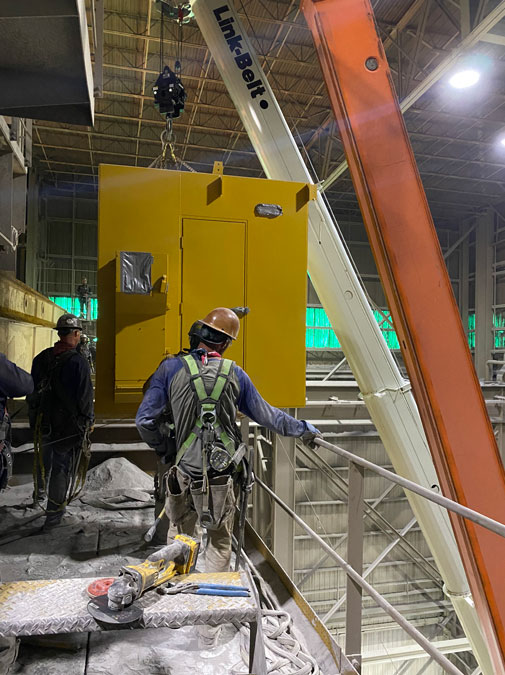

Morgan employee working on a DC to AC upgrade

Essential Upgrades

We collaborate with our knowledgeable customers to build custom cranes that meet their specific needs. There’s no detail left under-engineered. We don’t have pieces like gear boxes that we pick and place because it is all custom for each project. This means from girder width to a crane operator’s comfort in a cab are all considered as a new custom crane gets put together.

Before you invest in a new crane, our team of engineers can help you make sure it’s your best option. Our crane upgrades allow facilities to improve safety, efficiency, and productivity without having to purchase a brand-new crane.

Crane technician troubleshoots issue from Crane Management station off of the crane.

Crane Management Software

It can be surprising to learn that severe and continuous severe duty cranes can put on hundreds of miles of wear each year, even though they only have a couple of hundred feet of rail. Modern advancements, like Morgan Crane Management, make it easier than ever to be informed about an issue and how to correct it. With Morgan CM, your crane’s data is at your fingertips via critical system monitors on a one-to-one 3D model. Whenever a component needs preventative maintenance or a fault occurs, it alerts the operator immediately.

Site Services technicians upgrading control house for an existing Morgan crane.

Partial Crane Upgrades: DC to AC

Custom cranes built in the 1990s were built with technology that couldn’t produce the torque required for hoisting with an AC motor, so AC motors were only applied to bridges and trolleys. AC tech has caught up to the demands. Now, it can be used for hoisting. It’s becoming increasingly challenging to source replacement parts for DC cranes, making crane upgrades to AC a more time and cost-efficient solution.

Unlike DC cranes, AC cranes have been the benefactor of many of the recent innovations in material handling technology. Even if we aren’t the OEM, our team can design, manufacture, and install all the necessary changes for your DC to AC conversion.

Morgan ladle crane pouring molten steel

Strength of Steel

When it comes to building a custom crane, the choice of materials is critical. Our cranes owe much of their longevity to the amount of high-quality steel used in their construction. Morgan cranes are often heavier than others because of the increased steel content. This durability ensures that Morgan cranes are not just equipment but long-term investments in efficiency and safety. With regular maintenance, Morgan cranes can last lifetimes.

Discover the Morgan Difference in Cranes

At Morgan, we take pride in creating custom cranes that are not just tools but partners in your industrial endeavors. We’re here to elevate your operations with cutting-edge technology and exceptional durability. Through DC to AC conversions, custom-engineered cranes, and more. Contact us today to learn more about upgrading your crane with the most up-to-date control and safety features.