Piece by Piece: Overhead Cranes Explained – Part 5 – Control House

/ Blog

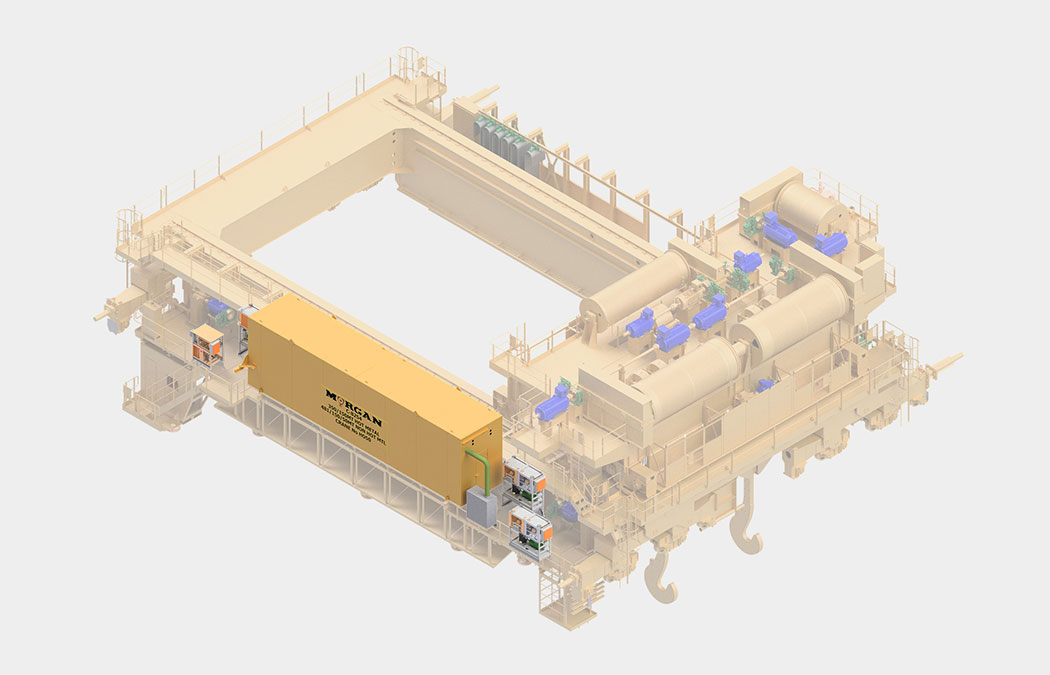

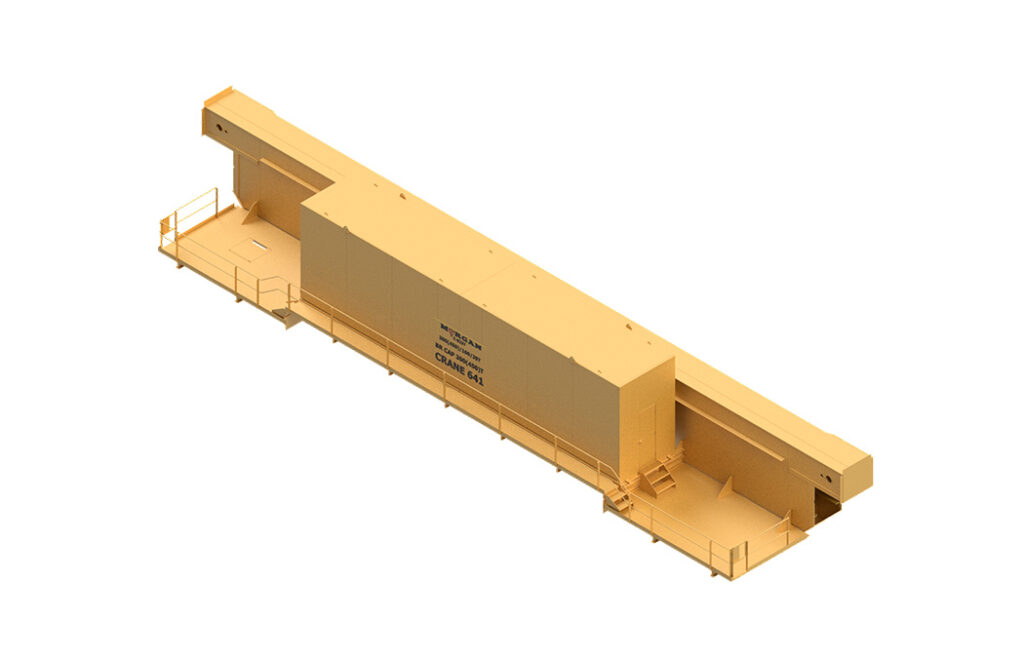

The control house serves as a central hub for the overhead crane controls and requires careful attention when designing a new crane. At Morgan Engineering, our expertise in manufacturing overhead bridge cranes extends to every component. Overhead cranes are composed of several critical pieces: trolley, bridge, cab, and control house. For this edition of the series, we will break down the importance of the control house.

If you haven’t already, review our previous parts of Overhead Cranes Explained for a comprehensive understanding of overhead crane parts.

A Crane Control House Defined

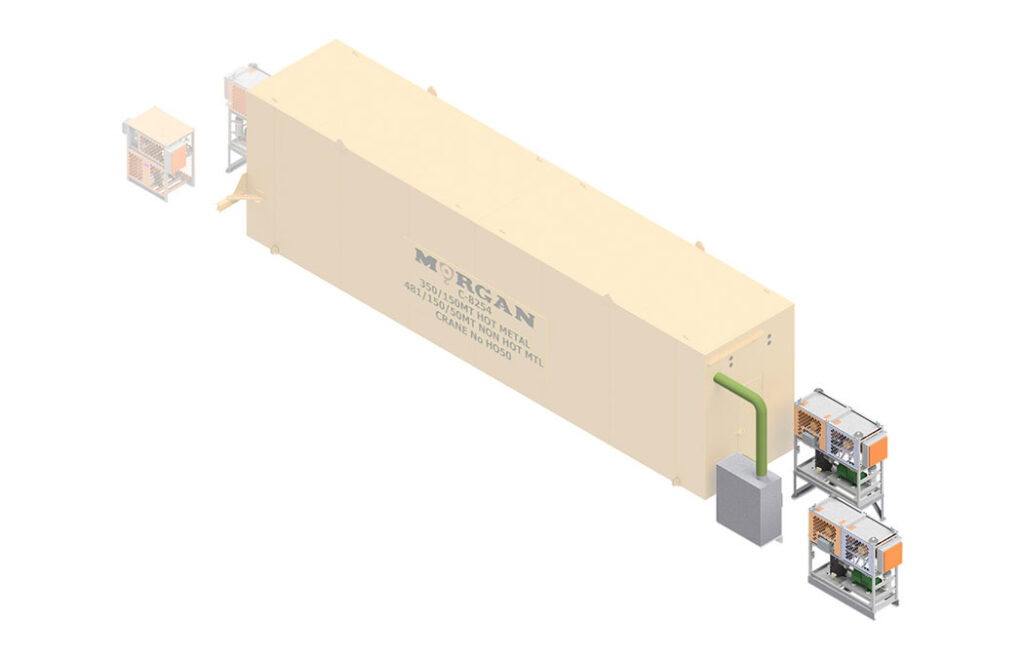

A control house with all of its control panels is where all the electrical parts are contained. This enclosed space maintains climate control for the electronic parts responsible for making the motions of an overhead crane possible and improving crane safety.

The electronics inside an overhead crane control house consist of disconnect switches, power regeneration equipment, variable frequency drives, motion control hardware, PLC’s, and HVAC equipment, all required to make the crane operate safely, reliably, and efficiently. Additionally, software packages such as Crane Management, No Fly Zones, and Automated Positioning can be incorporated.

Key overhead crane parts within a control house include:

- Insulated structure

- Cabinets

- Wire ways or race ways

- Overhead trolley rail system

- Walkways

- Air Conditioning Equipment

Control House Insulated Structure

Overhead crane controls are typically housed in a metal cabinet, a series of cabinets, or a control house. These structures safeguard all the electrical drives and the “brain” of the crane, which is known as a programmable logic controller (PLC). The PLC serves as the control center for the crane, directing all its movements and functions.

The control house of an overhead bridge crane contains and protects control cabinets in extreme environments. When designing a crane, the control house components are chosen based on the installation environment. Heat and dirt can have a big impact on what is included. Positive pressure units are used to ensure even less dirt gets in the contained space.

Morgan’s HVAC solutions offer 100% redundancy, meaning if one unit fails, the other can keep up and allow production to continue. This space also provides a cool room for the maintenance team when they are completing work. Typically, each AC system consists of multiple evaporators to make sure cool air is constantly and evenly distributed. The systems are thermostatically controlled so that cool air is provided even when the crane is not in use to be sure the controls stay in safe conditions.

In tandem with the AC units are positive pressure units. These work to keep the inside of the control house a couple of PSI (pounds per square inch) higher than outside. This essentially helps to keep dirt and debris from entering. When the man door is opened, for example, the seal is broken, and the positive pressure units will compensate to build the PSI back to where it is programmed to stabilize.

Control House Cabinets

Cabinets can be used outside of a control house to keep the same controls safe, but at Morgan, we almost exclusively design control houses. These grey metal cabinets house the PLC, motor controls, power distribution, safety controls, and any other wiring for the overhead bridge crane.

Wire Ways or Race Ways

Wire ways allow for wires to run to and from where they’re needed without restriction between the cabinets, essential for integrating and maintaining the complex network of overhead crane controls.

Overhead Trolley Rail System

Mounted to the ceiling of an overhead crane’s control house, an overhead trolley rail system provides a solution to pick up material and move it toward a door. These are helpful when moving variable frequency drives, active front-end modules, transformers, and other heavy electrical equipment, demonstrating the intricacy and thoughtfulness of our overhead crane components design.

Walkways

Depending on the size of the control house, extra walkways will be added for accessibility to meet OSHA requirements for crane safety and customer needs.

Additional Features

Modern control houses provide a range of additional amenities, including desks for reviewing drawings, fire alarm systems, and cabinets for storing routine maintenance items like filters and grease. These features highlight the comprehensive nature of overhead crane parts and their importance in ensuring crane safety and functionality.

Control House Design

Designing the perfect overhead crane control house involves considering the crane’s dimensions, control requirements, budget, and operating environment. Our engineers collaborate closely with clients to develop custom control house solutions that meet the necessary requirements.

Custom Engineering from Concept to Crane

At Morgan Engineering, each department collaborates on every aspect of our overhead cranes. Contact our crane experts, they have decades of expertise work for you with our custom crane solutions.

Follow Morgan Engineering on social media for the latest updates in our Overhead Cranes Explained series. Find us on Facebook, LinkedIn, X (formerly Twitter), YouTube, and Instagram.